We would like to describe you the process of the production of our high quality, fully handmade welted shoes and handmade welted or wooden nailed boots.

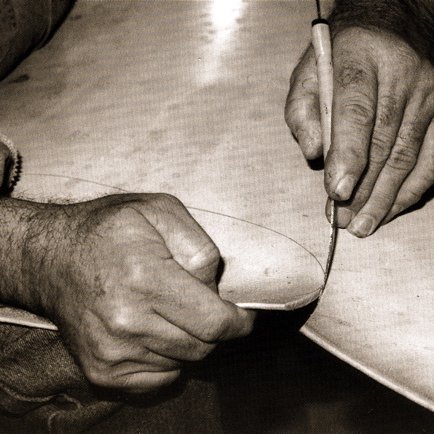

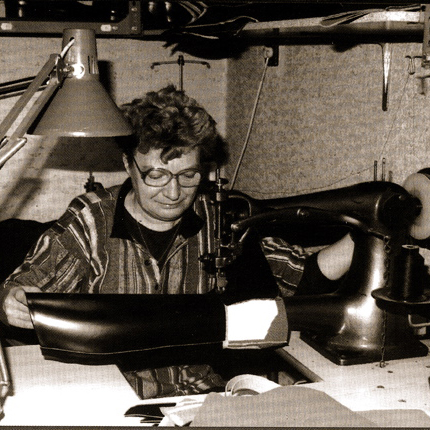

The first step is to take the measurements precisely, then we tailor the elements from the chosen leather, the upper and the lining leather too. The edges are thinned and the leathers are put together with a special, natural stick.

For boots, we fix and sew the stiffening material, which changes according to the model and the special needs. In addition in case of model with zip, we fix the zip in too, then we finish the upper part.

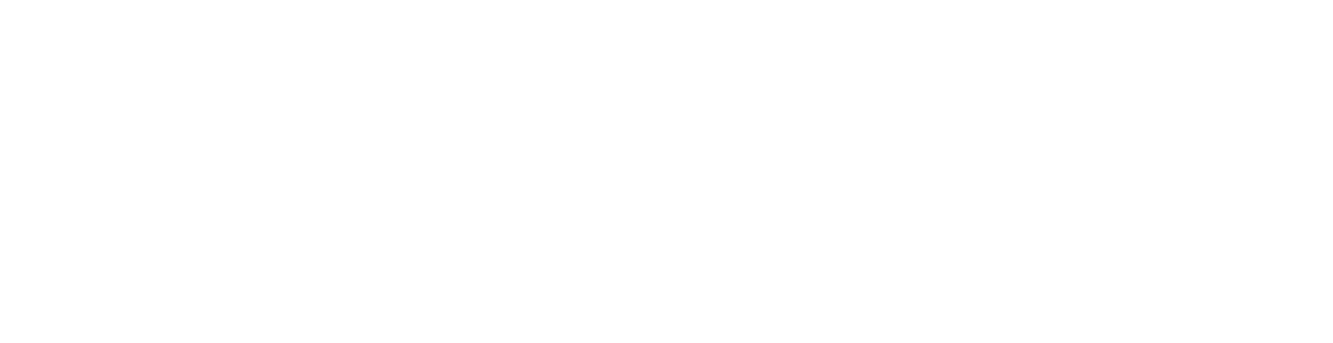

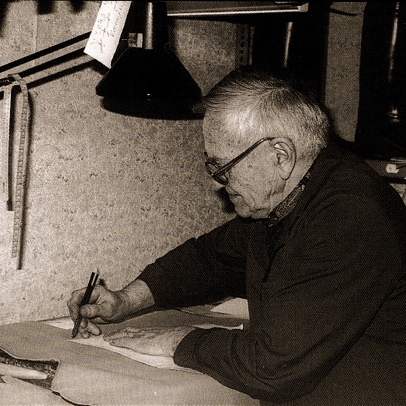

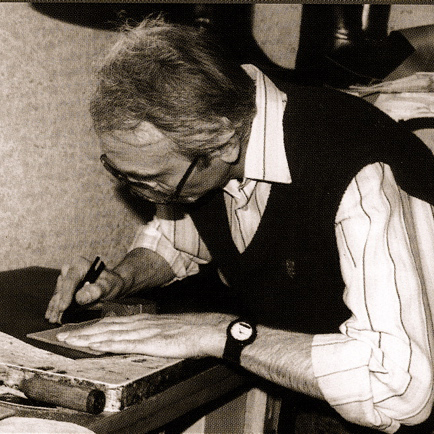

We adapt the chosen shaped shoe or boot tree to the given measurements to gain the individual leg and foot shape. We fix the sole lining and the toe cap, crust and the flank brace are placed to the upper part, then finally we fix it with the special stick mentioned above. Before placing it into the boots, shoes, we make the materials a bit wet so they can be more flexible and easier to work with. In case of handsewn footwear, we form the sewing ditch.

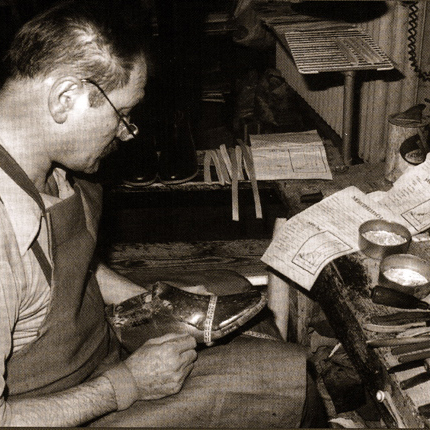

We fix the upper part to the last with a special technique, then according to the selected technology, we do the solework with sewing or wooden nails and we place the heels too.

If the method is hand sewing, we frame as well.

We take out the tree and place the sole lining.

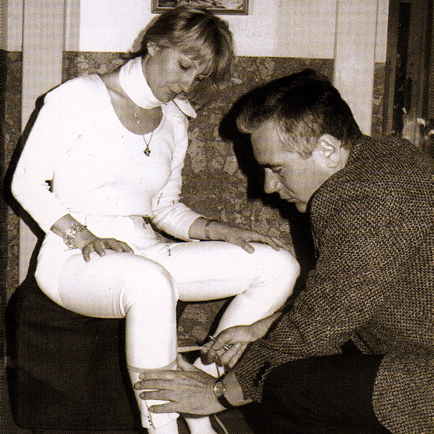

In case of boots, one of the most important parts of the procedure starts, which is putting the boot tree in. With the help of it, we can obtain the precise measurements and the final, elegant shape of the boots. During this procedure the leather is made damp a little bit, so as to make it less stubborn, and to make it easier to form. The boot tree is left in the boots for at least 2-3 days, therefore the leather can get the wished shape perfectly.

Finally we flame the boots, so that the wrinkles would be smoothered.

After all comes the creaming, cleaning and the burr is removed from the edge of the sole. It is called the finishing process.